As global manufacturing moves toward higher efficiency, tighter tolerances, and greater cost control, traditional machining methods are no longer meeting the demands of modern production. This shift has pushed many manufacturers to reconsider how metal components—especially fasteners and precision parts—are made. One process gaining renewed attention is cold heading, a forming technology that delivers speed, strength, and scalability without compromising quality.

But what exactly is driving this transition? Below, we explore the key reasons why cold heading is becoming the preferred choice across industries.

In today’s competitive manufacturing environment, consistency at scale is no longer optional—it is essential. Industries such as automotive, construction, electronics, and industrial equipment rely on millions of identical components that must perform reliably under stress.

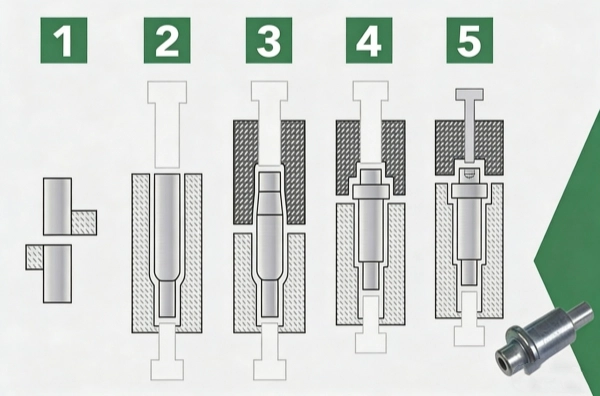

Cold heading excels in high-volume production, as it forms parts using precision dies rather than cutting material away. Once the tooling is properly set, every cycle produces components with nearly identical dimensions, weights, and mechanical properties. This repeatability significantly reduces variation between batches, which is critical for automated assembly lines and quality-sensitive applications.

Compared with machining, where tool wear and material inconsistencies can introduce variation, cold heading offers a stable and predictable manufacturing process that supports mass production with minimal deviation.

One of the most compelling reasons manufacturers adopt cold heading is cost efficiency. Unlike machining, which removes excess material and generates scrap, cold heading reshapes metal wire or rod into its final form with near-zero material waste.

Key cost-saving advantages include:

• Lower raw material consumption, as nearly all input material becomes part of the finished product

• Shorter cycle times, often producing parts in seconds rather than minutes

• Reduced labor requirements, especially when integrated with automated feeding and inspection systems

• Minimal secondary operations, such as cutting or finishing

Although initial tooling costs may be higher, cold heading delivers a strong return on investment (ROI) for medium- to high-volume production runs. Over time, the savings in material, energy, and labor far outweigh the upfront setup expenses.

Strength is another major factor behind the growing popularity of cold heading. Because the process forms metal without cutting the grain structure, it preserves and redirects grain flow to follow the shape of the part.

This continuous grain flow results in:

• Higher tensile and fatigue strength

• Improved resistance to cracking and impact

• Better performance under dynamic loads

For critical components such as bolts, screws, pins, and structural fasteners, this enhanced mechanical integrity is invaluable. In contrast, machined parts often have interrupted grain structures, which can weaken stress points and reduce service life.

As manufacturers increasingly prioritize durability and safety, cold heading offers a clear structural advantage.

Cold heading is best known for fastener production, but its applications extend far beyond standard bolts and screws. Thanks to advancements in multi-station cold heading machines, manufacturers can now produce complex geometries with multiple forming steps in a single cycle.

Industries that benefit most include:

• Automotive and transportation, for high-strength fasteners and connectors

• Construction and infrastructure, where load-bearing reliability is critical

• Electronics and appliances, requiring small, precise, repeatable components

• Industrial machinery, where durability and dimensional accuracy matter

Cold heading is especially well-suited for symmetrical or axis-based parts produced in large quantities, making it a strategic choice for manufacturers focused on efficiency and scalability.

Beyond immediate cost and performance benefits, cold heading aligns well with long-term manufacturing goals. The process supports automation, reduces energy usage per part, and minimizes material waste—key factors in sustainable production strategies.

As equipment becomes more advanced, modern cold heading lines now integrate:

• Real-time quality monitoring

• Automated defect detection

• Compatibility with Industry 4.0 systems

These improvements make cold heading not just a cost-saving solution, but a future-ready manufacturing process capable of scaling with market demand. For manufacturers planning long production cycles and global supply stability, cold heading offers both reliability and adaptability.